Using a Hunter Gas gun to deploy a space station from the moon.

Showing posts with label Major Topic --- Space: Flying Rocket Proposition. Show all posts

Showing posts with label Major Topic --- Space: Flying Rocket Proposition. Show all posts

Tuesday, February 26, 2013

Friday, January 20, 2012

Burt Rutan interview

Popular Mechanics H/T Transterrestrial Musings

quote:

Comment:

Just my opinion, and two cents here, but the problem may be that too much is expected from a single launch system. If the Stratolaunch, or Birdzilla as some call it, can solve the safety problem, then some other technology can solve the other problems.

Spacex will most likely attempt to make Birdzilla launch platform fully reusable, which will help with the cost problem.

As for the rest of a comprehensive solution, you can look at other systems to help with costs from LEO on outward. For example, Quicklaunch can get materials into space cheaply. If feasible, a LOXLEO system can skim atmospheric gases from LEO and use it to power spacecraft after achieving orbit, while reducing costs still further. By combining these two systems, you could leverage a small payload of hydrogen from Quicklaunch into much more by using a LOXLEO system. Once you have the water in orbit, you can then split it into hydrogen and oxygen. This could support missions to cis Lunar space where the moon can be further exploited into a base for interplanetary exploration and development. Thus, not all of the requirements needed will come from one system, but a series of systems.

quote:

To allow public access to orbit, we would need breakthroughs that would lower the cost by a lot more than an order of magnitude and increase safety by a factor of 100 as compared to every launch system used since the first manned space flight. I think airborne launch will be a significant part of the safety solution. Breakthroughs to do the rest of the job are unknown.

Comment:

Just my opinion, and two cents here, but the problem may be that too much is expected from a single launch system. If the Stratolaunch, or Birdzilla as some call it, can solve the safety problem, then some other technology can solve the other problems.

Spacex will most likely attempt to make Birdzilla launch platform fully reusable, which will help with the cost problem.

As for the rest of a comprehensive solution, you can look at other systems to help with costs from LEO on outward. For example, Quicklaunch can get materials into space cheaply. If feasible, a LOXLEO system can skim atmospheric gases from LEO and use it to power spacecraft after achieving orbit, while reducing costs still further. By combining these two systems, you could leverage a small payload of hydrogen from Quicklaunch into much more by using a LOXLEO system. Once you have the water in orbit, you can then split it into hydrogen and oxygen. This could support missions to cis Lunar space where the moon can be further exploited into a base for interplanetary exploration and development. Thus, not all of the requirements needed will come from one system, but a series of systems.

Thursday, January 12, 2012

Why make rockets reusable?

Spacex is joining in on the Birdzilla project, which will attach a Falcon rocket to the underside of a very large plane. I think that could help get the first stage back to the launch site with the minimum amount of hardware and fuel. ( my 2 cents here)

Saturday, October 15, 2011

Space Companies Hatch Plans for Reusable Rockets

Technology Review

- In a speech at the National Press Club in Washington, D.C., in late September, Elon Musk, the CEO and chief technology officer of SpaceX, announced plans to develop a fully reusable version of the company's Falcon 9 rocket. ...I've come to the conclusion that it can be solved, and SpaceX is going to try and do it."

- Musk is backing up his speech with development work.

- SpaceX is not the only company actively working on an orbital reusable launch vehicle. Blue Origin, the secretive aerospace company founded by Amazon.com CEO Jeff Bezos, has NASA funding to mature the design of a space vehicle that could be launched on existing expendable rockets, such as the Atlas V.

Friday, September 30, 2011

Electrodynamic Tether Propulsion- can you use it for Single Stage to Orbit?

The idea is to get that final bit of thrust needed in order to get to orbit. By the time a spacecraft is to that point, it will be hypersonic, but less than orbital velocity. The idea is to be able to reduce mass using propellant-less thrust. The same system can be used later for reentry as well.

In an earlier post, getting energy from reentry was discussed so as to provide active cooling. That method entails a means to reject energy into space by way of a solid state laser. By using a similar method, generating electricity from heat, you can store- via a capacitor- some of these electrons not used for active cooling. Upon reaching sufficient altitude, deploy an electrodynamic tether and send the current into the tether which will add lift. That gives a propellant-less boost, saving mass and helping get to orbit. The same tether's current can be reversed and be useful in storing electrons for the descent back down. The energy will go into the capacitor, causing drag, while the tether will used a little later on in order to provide lift so as to slow down the descent. This bleeds off energy while keeping the use of mass to a minimum.

Both systems, laser cooling, and electrodynamic tethers, will be useful in ascent and descent, while helping save enough mass so as to make the Single Stage to Orbit concept more feasible.

In an earlier post, getting energy from reentry was discussed so as to provide active cooling. That method entails a means to reject energy into space by way of a solid state laser. By using a similar method, generating electricity from heat, you can store- via a capacitor- some of these electrons not used for active cooling. Upon reaching sufficient altitude, deploy an electrodynamic tether and send the current into the tether which will add lift. That gives a propellant-less boost, saving mass and helping get to orbit. The same tether's current can be reversed and be useful in storing electrons for the descent back down. The energy will go into the capacitor, causing drag, while the tether will used a little later on in order to provide lift so as to slow down the descent. This bleeds off energy while keeping the use of mass to a minimum.

Both systems, laser cooling, and electrodynamic tethers, will be useful in ascent and descent, while helping save enough mass so as to make the Single Stage to Orbit concept more feasible.

Thursday, September 29, 2011

Laser cooling for spacecraft reentry

The usual technique is to cool things down to near absolute zero. But the proposition here is a bit different. The problem to be solved is getting rid of a lot of heat that does unpleasant things to spacecraft. What to do about this heat?

Can you cool something large that is really hot? How? I am currently looking at solid state lasers. Now, what happens when you do the laser cooling a bit differently? Let's say that something's really hot and you can convert that to electricity, and then use that electricity to start up a laser. Send that light energy out of the system by way of the laser. The laser could be sent out into space, perhaps in a convenient direction, of course.

Is it possible to use the heat of reentry to make this electricity and then convert it to a laser that is fired into space? The energy is rejected into space away from the vehicle in a form that does it no harm. The energy loss to the system is the means by which the spacecraft can survive reentry.

The laser produces no thrust as photons have no mass. The production of electricity leads to energy losses, which is normally an inefficiency, but in this case, it is an advantage, as that leads to the cooling that we are after.

I'll look further into this in order to figure if this is a practical way of approaching this problem.

Can you cool something large that is really hot? How? I am currently looking at solid state lasers. Now, what happens when you do the laser cooling a bit differently? Let's say that something's really hot and you can convert that to electricity, and then use that electricity to start up a laser. Send that light energy out of the system by way of the laser. The laser could be sent out into space, perhaps in a convenient direction, of course.

Is it possible to use the heat of reentry to make this electricity and then convert it to a laser that is fired into space? The energy is rejected into space away from the vehicle in a form that does it no harm. The energy loss to the system is the means by which the spacecraft can survive reentry.

The laser produces no thrust as photons have no mass. The production of electricity leads to energy losses, which is normally an inefficiency, but in this case, it is an advantage, as that leads to the cooling that we are after.

I'll look further into this in order to figure if this is a practical way of approaching this problem.

Saturday, September 24, 2011

Skylon spaceplane

NextBigFuture post on Feb 7 , 2011

This looks like a promising SSTO concept. It really looks like a flyable rocket. It combines rocketry with jet engines in an all-in-one package, which confers reusability and fast turnaround potential via mass reduction. Mass is your number one enemy in getting to orbit. The more mass, the more propellant needed. Since propellant itself has mass, this increases the mass penalty even further, and so on.

Consider the now retired Space Shuttle: it's liftoff mass was 4.47 million pounds, with a payload capacity of 53000 pounds. The the liftoff mass to payload mass ratio was 83 to 1. On the other hand, the proposed Skylon does much better - 23 to 1.

The Skylon people hope it can be reused up to 200 times. Presumably, since it will take off and land like a plane, it should have a fast turnaround time. Thus, it promises to fulfill what Elon Musk of SpaceX once described as the Holy Grail of rocketry.

I will study the pdf file about it and report more on this as I learn more.

This looks like a promising SSTO concept. It really looks like a flyable rocket. It combines rocketry with jet engines in an all-in-one package, which confers reusability and fast turnaround potential via mass reduction. Mass is your number one enemy in getting to orbit. The more mass, the more propellant needed. Since propellant itself has mass, this increases the mass penalty even further, and so on.

Consider the now retired Space Shuttle: it's liftoff mass was 4.47 million pounds, with a payload capacity of 53000 pounds. The the liftoff mass to payload mass ratio was 83 to 1. On the other hand, the proposed Skylon does much better - 23 to 1.

The Skylon people hope it can be reused up to 200 times. Presumably, since it will take off and land like a plane, it should have a fast turnaround time. Thus, it promises to fulfill what Elon Musk of SpaceX once described as the Holy Grail of rocketry.

I will study the pdf file about it and report more on this as I learn more.

Thursday, September 22, 2011

Blue Origin's pedigree, second stage recovery IV

The title may appear to be an oxymoron, but stick with me.

I'll start with the present and work backwards in time. Blue Origin is developing the New Shepard, which is a suborbital craft. It appears to be designed for space tourism, not for space exploration. Perhaps at some point, there may be more ambitious projects for this concept, but this is all I know for now.

The New Shepard is based upon the DC-X design. It was developed in conjunction with Reagan's Strategic Defense Initiative , and subsequently transferred to NASA in the Clinton era. This craft was intended to start with suborbital flights and then orbital flights as experience and knowledge was gained. It was intended to be a SSTO project, which had its roots in some research done in the Apollo Era, looking forward to post Apollo, now known as the Shuttle Era.

The DC-X really didn't get that far in achieving its goals. But let's look at its origins, as we continue going back into time. A European variant of an integral Single Stage to Orbit design, called BETA, was itself a consequence of a design that didn't get off the drawing boards.

Excerpt:

The BETA concept is characterized by the following features:

The author (Dietrich E Koelle?) came to the following conclusions:

"From the very principle the BETA Concept seems to be the final solution for the space transportation problem since it combines operational simplicity with lowest cost both for development and specific payload cost."

But it wasn't implemented.

But where did the BETA come from? It was an updated version of Douglas SASSTO, from the Apollo Era.

The SASSTO was intended to put a small capsule into orbit by using ideas from S-IVB upper stage of the Apollo Era Saturn rocket.

Alright, now note this:

A second stage recovery wouldn't be necessary if there's no second stage. You will need a powerful enough rocket to get to space, plus solve the knotty problem of finding a way to get back without destroying the rocket on reentry. That's a technical problem that may be solvable.

Blue Origin may not be interested in tackling this problem, but somebody may be able to. Anybody listening?

I'll start with the present and work backwards in time. Blue Origin is developing the New Shepard, which is a suborbital craft. It appears to be designed for space tourism, not for space exploration. Perhaps at some point, there may be more ambitious projects for this concept, but this is all I know for now.

The New Shepard is based upon the DC-X design. It was developed in conjunction with Reagan's Strategic Defense Initiative , and subsequently transferred to NASA in the Clinton era. This craft was intended to start with suborbital flights and then orbital flights as experience and knowledge was gained. It was intended to be a SSTO project, which had its roots in some research done in the Apollo Era, looking forward to post Apollo, now known as the Shuttle Era.

The DC-X really didn't get that far in achieving its goals. But let's look at its origins, as we continue going back into time. A European variant of an integral Single Stage to Orbit design, called BETA, was itself a consequence of a design that didn't get off the drawing boards.

Excerpt:

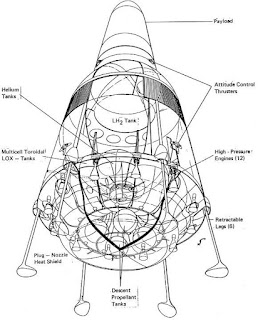

The BETA concept is characterized by the following features:

- A short conical body (small length/diameter ratio, low c.g.) with heat-shield for re-entry

- Use of the heat-shield as a plug-nozzle for performance increase

- A propulsion system consisting of 12 or more single high-pressure LH2/ LOX engines arranged around the central plug-nozzle (heat-shield)

- 6 retractable legs for the final vertical landing phase.

|

| Space Future.com |

- The development of a single stage ballistic space shuttle is feasible with the present technology.

- The transportation cost Earth-to-Orbit can be reduced to some 200 $/kg or less.

- The single-stage concept allows new possibilities for launch ranges since no

danger by expendable parts or stages has to be expected. This means that launches from and landings within Europe would be feasible. - The BETA Concept seems to be a solution for specific European requirements since there is no manned space flight programme, there does not exist the 500 km/550 space station target orbit, and there is no requirement for a large cross range capability.

"From the very principle the BETA Concept seems to be the final solution for the space transportation problem since it combines operational simplicity with lowest cost both for development and specific payload cost."

But it wasn't implemented.

But where did the BETA come from? It was an updated version of Douglas SASSTO, from the Apollo Era.

The SASSTO was intended to put a small capsule into orbit by using ideas from S-IVB upper stage of the Apollo Era Saturn rocket.

Alright, now note this:

Bono noticed that the S-IVB stage, then just starting to be used operationally, was very close to being able to reach orbit on its own if launched from the ground. Intrigued, Bono started looking at what missions a small S-IVB-based SSTO could accomplish, realizing that it would be able to launch a manned Gemini capsule if it was equipped with some upgrades, notably an aerospike engine that would improve the specific impulse and provide altitude compensation.[2] He called the design "SASSTO", short for "Saturn Application Single-Stage To Orbit". [comment: emphasis mine, quite impressive that this rocket existed almost half a century ago.]It appears that a renewed effort at an SSTO could achieve the results desired. The inflatable heat shield could be used in place of aerospike engines, if these are too difficult to perfect. They may even be used as a safety margin, since the mass of such a device should be small.

A second stage recovery wouldn't be necessary if there's no second stage. You will need a powerful enough rocket to get to space, plus solve the knotty problem of finding a way to get back without destroying the rocket on reentry. That's a technical problem that may be solvable.

Blue Origin may not be interested in tackling this problem, but somebody may be able to. Anybody listening?

Hybrid cars may have a useful lesson to teach, second stage recovery III

Hybrid cars use regenerative braking in order to recharge their batteries. Could this principle have other applications? With respect to making rockets fully reusable, could the heat energy from reentry be used for some useful purpose? The idea I had, which may or may not be practical, is to use that heat in an active cooling system.

How would this work? Here are a couple ideas in the roughest form. I haven't had time to refine this, so please excuse this if it is impractical or full of errors. I wrote it last night just prior to retiring for the evening.

I wonder what would happen if you were to somehow use the heat of reentry for thrust. Set up a heat exchanger and run some reaction mass through the heat exchanger and send the hot gas out a nozzle for thrust. Would that be feasible?

Another idea:

Let's say that you want to harvest the heat generated by reentry for running a cryogenic cooler which in turn cools the heat shield. The heat shield provides energy for a Stirling engine, which is attached to another Stirling engine in reverse.

A Stirling engine in reverse is a cryogenic device, which can take the hot side of the energy generator and make it cold again. The cold side feeds back into the energy generator's cold side. This will cycle back and forth synergistically providing cooling to the shield, while the shield provides energy for the cooler.

It occurred to me that you could use this on the way up as well. For example, the rocket nozzle needs to be cooled down. Let's say you want to condense some oxygen out of the atmosphere on the way up. You can attach this system to the cooling system of the nozzle so as use that heat for the generation of oxygen by condensation from the cryocooler. The oxygen can be used for thrusting on the way down, or on the way up.

Update:

I am spending some time reading up on the subject. On the subject of reentry during the Apollo Era, I found that the space capsules were designed to produce what is called a "bow shock", which deflected some of the energy away from the craft. It also produced a lot of drag, which was needed to slow down the capsule.

With respect to the idea mentioned above, there has been some study on the concept. This has led me to a discussion of aerospike engines, but how did I get here? What does that have to do with reentry? Puzzling.

I will stop this post here. Too much detail needs to be mastered. Frankly, I don't know what I'm doing, so maybe it is best to stop posting about this for now. Perhaps, after awhile, I will return to it.

Update:

Inflatable heat shields are an intriguing possibility. I'll have to return to this later.

How would this work? Here are a couple ideas in the roughest form. I haven't had time to refine this, so please excuse this if it is impractical or full of errors. I wrote it last night just prior to retiring for the evening.

I wonder what would happen if you were to somehow use the heat of reentry for thrust. Set up a heat exchanger and run some reaction mass through the heat exchanger and send the hot gas out a nozzle for thrust. Would that be feasible?

Another idea:

Let's say that you want to harvest the heat generated by reentry for running a cryogenic cooler which in turn cools the heat shield. The heat shield provides energy for a Stirling engine, which is attached to another Stirling engine in reverse.

A Stirling engine in reverse is a cryogenic device, which can take the hot side of the energy generator and make it cold again. The cold side feeds back into the energy generator's cold side. This will cycle back and forth synergistically providing cooling to the shield, while the shield provides energy for the cooler.

It occurred to me that you could use this on the way up as well. For example, the rocket nozzle needs to be cooled down. Let's say you want to condense some oxygen out of the atmosphere on the way up. You can attach this system to the cooling system of the nozzle so as use that heat for the generation of oxygen by condensation from the cryocooler. The oxygen can be used for thrusting on the way down, or on the way up.

Update:

I am spending some time reading up on the subject. On the subject of reentry during the Apollo Era, I found that the space capsules were designed to produce what is called a "bow shock", which deflected some of the energy away from the craft. It also produced a lot of drag, which was needed to slow down the capsule.

With respect to the idea mentioned above, there has been some study on the concept. This has led me to a discussion of aerospike engines, but how did I get here? What does that have to do with reentry? Puzzling.

I will stop this post here. Too much detail needs to be mastered. Frankly, I don't know what I'm doing, so maybe it is best to stop posting about this for now. Perhaps, after awhile, I will return to it.

Update:

Inflatable heat shields are an intriguing possibility. I'll have to return to this later.

Wednesday, September 21, 2011

Second stage recovery, II

Prior to coming across the flyable Saturn V stuff, I was reading up on making the second stage survivable. In order to accomplish that, I checked into some information about the Shuttle's heat protective tiles.

It looks like the mass of the tiles was such that it could be added to a second stage so that it doesn't burn up on reentry. The second part is to assure it isn't damaged as it contacts the water. Of course, there would be parachutes in order to slow down the impact, but even so, the impact may be significant enough to cause damage. So far, I've haven't checked any further on that possibility.

It looks like the mass of the tiles was such that it could be added to a second stage so that it doesn't burn up on reentry. The second part is to assure it isn't damaged as it contacts the water. Of course, there would be parachutes in order to slow down the impact, but even so, the impact may be significant enough to cause damage. So far, I've haven't checked any further on that possibility.

Flyback version of the Saturn rocket

When I saw this, I was surprised, to say the least. Something that I've written about here several times, was actually considered during the Apollo Era. A bit reassuring that, even though the idea wasn't mine, that it could be feasible after all. If flyback version of the Saturn first stage is feasible, surely a smaller version is just as feasible, if not more.

Here are other links to more information on the proposition. A picture down below:

More pics below:

The above schematics were of an early Shuttle concept using Saturn V rocketry. The Saturn V was discontinued. It looks like this design may have given a faster turnaround than the SRB's, because of the ability to flyback, and to be refueled quickly.

Here are other links to more information on the proposition. A picture down below:

|

| Flyable rocket, first stage of the Saturn rocket in the Apollo Era |

The above schematics were of an early Shuttle concept using Saturn V rocketry. The Saturn V was discontinued. It looks like this design may have given a faster turnaround than the SRB's, because of the ability to flyback, and to be refueled quickly.

Monday, September 19, 2011

Second stage recovery

The SRBs from the Shuttle could be recovered. What about a second stage? Is it possible to do that? The goal would be to make a second stage that can get to orbit and be recoverable after completing its mission. It would be stacked on top a solid rocket booster, with a recoverable oribiter stacked on top of it.

Let's leave speculation about the design for another discussion, and consider the logistics of recovering it after its mission.

The Falcon 9 second stage can get to orbit. Now, suppose you could get it back in good shape. The location for splashdown would most likely have to be a long way from any land mass. Presumably, it would splash down in the Pacific.

The great distances would cause a delay. If you want a fast turnaround, this is a problem. How to overcome the vast distance back to Florida?

Idea: Put a rocket inside one of these planes. Why? To speed up processing. It may need to splash down in the Pacific, be transported by boat which docks at the nearest island with a suitable airport. The rocket is loaded in the plane and sent back to Florida and unloaded and processed for the next launch.

Boeing 747 Large Cargo

Aero Spacelines Super Guppy

Aero Spacelines Pregnant Guppy

It says on the link that the Pregnant Guppy actually transported the Saturn second stage rocket. The S-IV second stage dimensions were 40 feet long by 18 feet in diameter. The last stage of this rocket, which was never flown, was the Centaur. But the Centaur stage was the Earth Departure Stage. The second stage, presumably, could get you to orbit. (cross your fingers, there)

You might need to work on the size of the rocket, but since this kind of thing has been done before, it isn't out of the question.

Update 9/20/11:

This is actually an interesting subject. I've been reading about it this morning. It so happens that the Ares I second stage has a design very similar to the Saturn second stage mentioned. However, it is an expendable design.

Secondly, the cost of an Ares I is high, but can come down if there were more launches. The cost of launches can be brought down to a comparable cost of the Soyuz, which we are renting from the Russians. If you were to make the Ares fully reusable, frequent launches would be desirable.

Instead of a capsule on top, try putting a Dream Chaser on top. It may look something like this:

An Atlas V and an Ares I have about the same payload capacities. But the Ares I could be partly reusable and ultimately, it may be possible to make it fully reusable, if the second stage can be made to be recoverable.

There is surplus cargo capacity, so that there is more mass capacity for extra hardware in order to make this happen.

The first launches could use expendable second stage. Development can continue so as to make it fully reusable and then you can proceed to make the turnaround go faster.

Let's leave speculation about the design for another discussion, and consider the logistics of recovering it after its mission.

The Falcon 9 second stage can get to orbit. Now, suppose you could get it back in good shape. The location for splashdown would most likely have to be a long way from any land mass. Presumably, it would splash down in the Pacific.

The great distances would cause a delay. If you want a fast turnaround, this is a problem. How to overcome the vast distance back to Florida?

Idea: Put a rocket inside one of these planes. Why? To speed up processing. It may need to splash down in the Pacific, be transported by boat which docks at the nearest island with a suitable airport. The rocket is loaded in the plane and sent back to Florida and unloaded and processed for the next launch.

Boeing 747 Large Cargo

Aero Spacelines Super Guppy

Aero Spacelines Pregnant Guppy

It says on the link that the Pregnant Guppy actually transported the Saturn second stage rocket. The S-IV second stage dimensions were 40 feet long by 18 feet in diameter. The last stage of this rocket, which was never flown, was the Centaur. But the Centaur stage was the Earth Departure Stage. The second stage, presumably, could get you to orbit. (cross your fingers, there)

You might need to work on the size of the rocket, but since this kind of thing has been done before, it isn't out of the question.

Update 9/20/11:

This is actually an interesting subject. I've been reading about it this morning. It so happens that the Ares I second stage has a design very similar to the Saturn second stage mentioned. However, it is an expendable design.

Secondly, the cost of an Ares I is high, but can come down if there were more launches. The cost of launches can be brought down to a comparable cost of the Soyuz, which we are renting from the Russians. If you were to make the Ares fully reusable, frequent launches would be desirable.

Instead of a capsule on top, try putting a Dream Chaser on top. It may look something like this:

| http://en.wikipedia.org/wiki/File:Ares_I_Evolution.jpg |

|

| Dream Chaser on top of an Atlas |

There is surplus cargo capacity, so that there is more mass capacity for extra hardware in order to make this happen.

The first launches could use expendable second stage. Development can continue so as to make it fully reusable and then you can proceed to make the turnaround go faster.

Sunday, September 4, 2011

Dream Chaser

This looks like a contender for an actual system that may see some action in the future. Mind you, I'm not picking winners here. Not to say that someone else may get the nod.

Here's a screenshot from the SpaceDev site which shows an animated version of the Dream Chaser on top of a rocket, presumably an Atlas V.

One thing that I am checking out is if this will fit on top of an SRB, which was to be used with the Ares I rocket, now canceled. It would be a way to mate a reusable booster with the reusable Dream Chaser. Not that they would actually want to put their Dream Chaser on a solid rocket booster. In fact, the word is out that the Atlas V will launch the Dream Chaser.

Was the SRB ever in the running?

As for dimensions, the SRB and the Atlas V are very similar. Performance wise, well, I don't know. The SRB is supposed to fire for about 2 minutes. But it generates a lot of thrust. Both SRBs in the Shuttle configuration provided 83% of the liftoff thrust, but only 60% of the mass.

What that would mean in terms of altitude and velocity for a 25,000 pound craft, I can only guess. The shuttle weighed 10 times as much. A single SRB just might be enough to get to orbital velocity and altitude. But could it be recovered?

The Ares I was designed to send the Orion into orbit. The Orion's mass came in at twice what the Dream Chaser's. With far less mass, all the Dream Chaser may need is just a little more boost from its own onboard rockets in order to reach orbit. I'm not 100% sure of that, though. Maybe a lot less than 100%.

This isn't a flyable rocket, but it could all be 100% reusable, if the SRB could be recovered in good shape.

Thanks for coming by and have a great evening.

Here's a screenshot from the SpaceDev site which shows an animated version of the Dream Chaser on top of a rocket, presumably an Atlas V.

|

| http://www.spacedev.com/ |

Was the SRB ever in the running?

As for dimensions, the SRB and the Atlas V are very similar. Performance wise, well, I don't know. The SRB is supposed to fire for about 2 minutes. But it generates a lot of thrust. Both SRBs in the Shuttle configuration provided 83% of the liftoff thrust, but only 60% of the mass.

What that would mean in terms of altitude and velocity for a 25,000 pound craft, I can only guess. The shuttle weighed 10 times as much. A single SRB just might be enough to get to orbital velocity and altitude. But could it be recovered?

The Ares I was designed to send the Orion into orbit. The Orion's mass came in at twice what the Dream Chaser's. With far less mass, all the Dream Chaser may need is just a little more boost from its own onboard rockets in order to reach orbit. I'm not 100% sure of that, though. Maybe a lot less than 100%.

This isn't a flyable rocket, but it could all be 100% reusable, if the SRB could be recovered in good shape.

Thanks for coming by and have a great evening.

Tuesday, August 30, 2011

Would this work on a flying rocket?

The article on NextBigFuture is about using these for windmills, but could there be another application for them? It is stronger than carbon fiber.

In a comparison of reinforcing materials, the researchers found carbon nanotubes are lighter per unit of volume than carbon fiber and aluminum and had more than 5 times the tensile strength of carbon fiber and more than 60 times that of aluminum.

Just when I thought that the flying rocket idea was impractical.

Monday, August 29, 2011

Reusable Rockets, Part 5, I think

That's amusing. I don't even know how many of these posts I have. No matter. This is just for kicks. Not like I am actually going to make money off this, you know.

Anyway, the last post, ( I think), I mentioned that you could use inflatable wings. But what if you don't want to do that, or if it is impractical? Now that could be a problem, because the Falcon 9 doesn't have enough capacity to add a lot of hardware. Hardware weighs a lot and that is penalized very heavily when you are talking about getting to space. So, that leads me to the next brainstorm. Yuk, yuk.

You see, SpaceX has come out with the idea of the Falcon 9 Heavy. So, the idea came to me, why not use its capacity for lift as capacity for all this needed hardware that will make it reusable and that quick turnaround? You may want to save some fuel too, for maneuvering back toward the launch site.

But, you may protest, wouldn't this mean that you could carry less into orbit? But of course it would. On the other hand, with a fast turnaround, you could make the trip more often. With a reusable and refittable flying rocket, you could have a goal of launching every week for each rocket. If you had a fleet of these, you could conceivably launch every day!

Anyway, the last post, ( I think), I mentioned that you could use inflatable wings. But what if you don't want to do that, or if it is impractical? Now that could be a problem, because the Falcon 9 doesn't have enough capacity to add a lot of hardware. Hardware weighs a lot and that is penalized very heavily when you are talking about getting to space. So, that leads me to the next brainstorm. Yuk, yuk.

You see, SpaceX has come out with the idea of the Falcon 9 Heavy. So, the idea came to me, why not use its capacity for lift as capacity for all this needed hardware that will make it reusable and that quick turnaround? You may want to save some fuel too, for maneuvering back toward the launch site.

But, you may protest, wouldn't this mean that you could carry less into orbit? But of course it would. On the other hand, with a fast turnaround, you could make the trip more often. With a reusable and refittable flying rocket, you could have a goal of launching every week for each rocket. If you had a fleet of these, you could conceivably launch every day!

Saturday, August 20, 2011

The Evening Wrap, 8/20

I want to return to the flyable rocket proposition, if I may.

The Shuttle system seemed to me to be an incomplete design. If the idea was resusability and rapid turnaround, then it failed. But there were a number of accomplishments. Being able to return the orbiter was one and the recovery of the solid rocket boosters (SRB) was another. A third possibility was to reuse the external tank while still in orbit, but this never materialized.

It failed because, even though the orbiter returned to the launch site, it wasn't a fast turnaround. The same was true of the SRBs. And no effort was made to return the external tank or reuse it in space at all. This all came up short, but why? Could the Shuttle and the SRBs be processed faster? Could there have been a way to use the external tanks? Or was it just a flawed design, which needed to be improved upon?

I think it was the latter. The Shuttle was called upon to do too many things in order to satisfy too many people. Its primary purpose was lost in all this and was shoved back into a lower level of priority. It had to please Congressional districts, who wanted a piece of the business. This led to a SRB design which required that SRB's be sent from Utah to Florida- not very convenient. It led to the Challenger disaster because of the segmented rocket boosters failed to seal off hot gases which led to the disaster. Another factor was the Shuttle's main engines were run greater than capacity, which caused greater turnaround time, as well. Furthermore, it was called upon to deliver a lot of cargo, which required a much bigger orbiter. Too many objectives had to be met- it needed to be simplified and less ambitious.

Now, we can ask, what if? What if the orbiter was smaller and used boosters made and serviced in Florida, near the launch site? What if its only mission was to deliver small amounts of cargo unmanned, or just a few astronauts? The orbiter weighed over 100 tons. Could this have been improved upon? Given that 95% of what launches is fuel and oxidizer, a much smaller shuttle would have made a much smaller launch system feasible. One half of the size of the shuttle would have halved the size of the external tanks and SRB's. Or, you could have kept the size of the launch system the same, while improving the reusability of the remaining part that wasn't reused- the external tank.

If you have added flight capability to the external tank, or protective heat shield with some thrusters and parachutes, then you may have save the external tanks. But then, where do you splash down? But if the tanks were smaller, might it have been possible to make them flyable? On the other hand, if the tanks were small enough, might they have fit on top of a plane and sent back to Florida?

In other words, could have system been devised which would allow all the pieces to be collected, serviced, and reused in a shorter time frame? It seems like a little more thought may have made that possible.

Well, that's all for now. Thanks for coming by and have a great evening.

The Shuttle system seemed to me to be an incomplete design. If the idea was resusability and rapid turnaround, then it failed. But there were a number of accomplishments. Being able to return the orbiter was one and the recovery of the solid rocket boosters (SRB) was another. A third possibility was to reuse the external tank while still in orbit, but this never materialized.

It failed because, even though the orbiter returned to the launch site, it wasn't a fast turnaround. The same was true of the SRBs. And no effort was made to return the external tank or reuse it in space at all. This all came up short, but why? Could the Shuttle and the SRBs be processed faster? Could there have been a way to use the external tanks? Or was it just a flawed design, which needed to be improved upon?

I think it was the latter. The Shuttle was called upon to do too many things in order to satisfy too many people. Its primary purpose was lost in all this and was shoved back into a lower level of priority. It had to please Congressional districts, who wanted a piece of the business. This led to a SRB design which required that SRB's be sent from Utah to Florida- not very convenient. It led to the Challenger disaster because of the segmented rocket boosters failed to seal off hot gases which led to the disaster. Another factor was the Shuttle's main engines were run greater than capacity, which caused greater turnaround time, as well. Furthermore, it was called upon to deliver a lot of cargo, which required a much bigger orbiter. Too many objectives had to be met- it needed to be simplified and less ambitious.

Now, we can ask, what if? What if the orbiter was smaller and used boosters made and serviced in Florida, near the launch site? What if its only mission was to deliver small amounts of cargo unmanned, or just a few astronauts? The orbiter weighed over 100 tons. Could this have been improved upon? Given that 95% of what launches is fuel and oxidizer, a much smaller shuttle would have made a much smaller launch system feasible. One half of the size of the shuttle would have halved the size of the external tanks and SRB's. Or, you could have kept the size of the launch system the same, while improving the reusability of the remaining part that wasn't reused- the external tank.

If you have added flight capability to the external tank, or protective heat shield with some thrusters and parachutes, then you may have save the external tanks. But then, where do you splash down? But if the tanks were smaller, might it have been possible to make them flyable? On the other hand, if the tanks were small enough, might they have fit on top of a plane and sent back to Florida?

In other words, could have system been devised which would allow all the pieces to be collected, serviced, and reused in a shorter time frame? It seems like a little more thought may have made that possible.

Well, that's all for now. Thanks for coming by and have a great evening.

NDTV: Soon, India to have its own space shuttle

An engineering model of what scientists at the Indian Space Research Organisation (ISRO) call the re-usable launch vehicle, is currently housed at a secure and secret facility in Kerala. Covered with special heat resistant tiles, soon it will roar skywards.I saw this on the Free Republic website. It got my attention due to my interest in the flyable rocket concept, which could be a way to make access to space affordable.

The Free Republic commenters said that this was a rip off of the Boeing X-37, which has flown a couple of times in recent years. So, I started looking into the X-37. It is launched by an Atlas V, so it is not a fully reusable system. It also carries a payload onboad. It's total launch weight is only 11,000 pounds, which makes it a small vehicle. It does go to orbit and returns and lands like a plane.

The interesting thing to me is that it weighs 11,000 pounds and has these really short wings. Not knowing any better, I'd say something similar might be done with a rocket casing itself, thereby making a first stage flyable. After all, it seems rather pointless to have only a part of the launch system reusable. A Falcon 9 first stage should weigh no more than say an empty shuttle external tank, which came in at 50,000 pounds. I don't know what the Falcon 9 weighs while empty, and counting only the weight of the first stage.

It would seem that outside of SpaceX, there doesn't appear to be much interest in making the entire launch system reusable. But significant portions are already reusable. Frankly, it looks to me like something could already be put together that would make all of the system reusable, but would it have fast turnaround times? That is basically the whole point.

Wednesday, August 17, 2011

Study of the Shuttle RTLS abort mode

Why? Well, it occurred to me that if the Shuttle was designed to do this, perhaps it isn't an impossible maneuver.

It was designed to do a RTLS abort after the SRB's discontinued firing, which is a little over 2 minutes into the flight. Up to T plus 4 minutes, the maneuver was still possible.

The idea is to design a RTLS for the first stage of a reusable rocket. The second stage continues with the payload to orbit.

The trick in this proposed system is to have almost 95% of the entire mass at launch supported by this airframe. On second thought: why? You only need the structural support for the stack at launch. On the return to launch site, your mass is going to be much less, meaning the wings only need to support less than 5% of the launch mass. Therefore, the strongest part of the structure needs to resist gravity, which means straight down the middle.

On return, the wings can support the much lighter craft. My original thought was to have the tanks in the wings, but that means more weight supported by the wings, which is a non starter. That appears to be the stumbling block. Perhaps the wings can support the engines? The fuel would stay in the "fuselage".

It was designed to do a RTLS abort after the SRB's discontinued firing, which is a little over 2 minutes into the flight. Up to T plus 4 minutes, the maneuver was still possible.

The idea is to design a RTLS for the first stage of a reusable rocket. The second stage continues with the payload to orbit.

|

| http://en.wikipedia.org/wiki/File:Space_Shuttle_vs_Soyuz_TM_-_to_scale_drawing.png |

On return, the wings can support the much lighter craft. My original thought was to have the tanks in the wings, but that means more weight supported by the wings, which is a non starter. That appears to be the stumbling block. Perhaps the wings can support the engines? The fuel would stay in the "fuselage".

Tuesday, August 16, 2011

Airbus A350 and carbon fiber

The Airbus A350 is a family of long-range, wide-body jet airliners under development by European aircraft manufacturer Airbus. The A350 will be the first Airbus with both fuselage and wing structures made primarily of carbon fibre-reinforced polymer. [emphasis added] Wikipedia

Very interesting. This isn't consistent with what I was thinking earlier today about using inflatable wings- but it may be a better idea. Let's say you fashion a wing that doubles as a fuel tank. The entire structure could be a flying gas can, but that is already what it is.

Come to think of it, you need someplace to hold the motors in place, but how did the Airbus manage that? The Airbus design suggests that it could be done.

In case you are wondering, this post is about making a flying rocket. It would launch vertical and land horizontal. You could stack a second stage plus cargo on top of it.

Subscribe to:

Posts (Atom)